Description

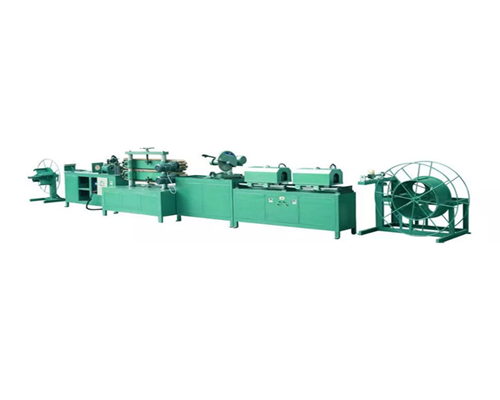

Metal hose mechanical forming machine

Metal hose mechanical forming machine is used to produce “Ω” shape metal hose.

MAIN PARAMETER

- Size range: DN8 ~ DN32

- Production speed: 2.5~3.5 m/min

- Strip thickness: 0.18-0.3 mm

- Material: sus304, 321 and 316L

- Dimension: L20000 x W1200 x H1600MM

- Weight: 3000 kg

- Power: 5KW

- Milled length: About 20 mets /roll

- Forming process: A. Strip decoiler/winder →B. Pipe welding →C. Cutting machine →D. Caterpillar →E. Forming head/reforming head →F. Take up

| No. | Size | Tube OD

(mm) |

Wall thickness

(mm) |

Hose ID

(mm) |

Hose OD

(mm) |

Pitch distance

(mm) |

Width of the strip

(mm) |

| 1 | DN8 | 10.3 | 0.18 | 8 | 11.3 | 2.7 | 31.8 |

| 2 | DN10 | 12.3 | 0.18 | 10 | 13.5 | 2.9 | 38.1 |

| 3 | DN12 | 15 | 0.18 | 12.3 | 16.3 | 3.2 | 46.6 |

| 4 | DN16 | 20 | 0.2 | 16.2 | 21.3 | 4.5 | 62.2 |

| 5 | DN20 | 23.5 | 0.25 | 20 | 25 | 4.5 | 73.0 |

| 6 | DN25 | 30 | 0.3 | 25 | 31.5 | 4.5 | 93.3 |

| 7 | DN32 | 39.5 | 0.3 | 33 | 41 | 4.5 | 123.2 |

| 8 | DN40 | 50 | 0.3 | 40 | 50 | 5.5 | 156.2 |

Forming Process Of The Machine

1. Decoiler

2. Welding

3. Caterpillar

4. Cutting

5. Forming head / Reforming head

6. Take up

PRODUCTS FROM THE MACHINE