Description

Features

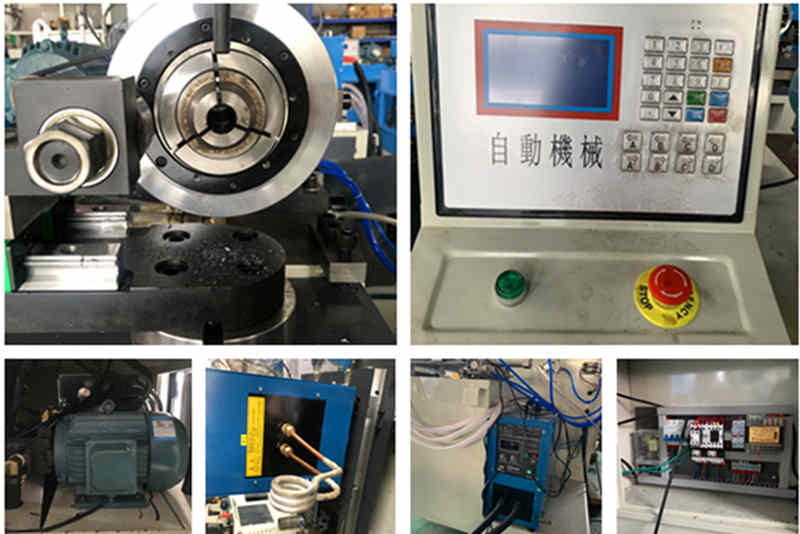

The automatic sealing machine is a self-developed product developed by our company on the basis of absorbing foreign advanced technology. It is controlled by PLC, hydraulically driven, and man-machine dialogue operation. It is easy to set up and input, manual and automatic arbitrary selection, and automatic conversion. The mobile foot switch has two functions: start and emergency stop. High security, with counting function. The machine has stable performance and high sealing efficiency, making it ideal equipment in the pipe processing industry.

Machine Details

Application

FAQ

1. What kind of pipe materials can sealed?

Carbon Steel, Stainless steel, Aluminum, Copper pipes, tubes.

According to following information to choose type:

1)Pipe/tube materials

2)Max. the outside diameter of the pipe/tube

3)Wall thickness range of the pipe/tube

4)Max sealing radius (general 1.5*OD)

5)sealing drawing or samples

1)Will provide operating video and manual with the machine.

2)Also welcome to our factory for training, we will arrange everything at our factory.4. What about your machine main component

1) PLC: Japan Mitsubishi

2) Servo motor: Japan Mitsubishi

3)Hydraulic system: Taiwan 7 Ocean

4)Main Motor: Siemens

5)Electric parts: Schneider

One year warranty after machine reached customer’s workshop.

And use famous brand components for a long working lifespan.